Service. Supply and Certification

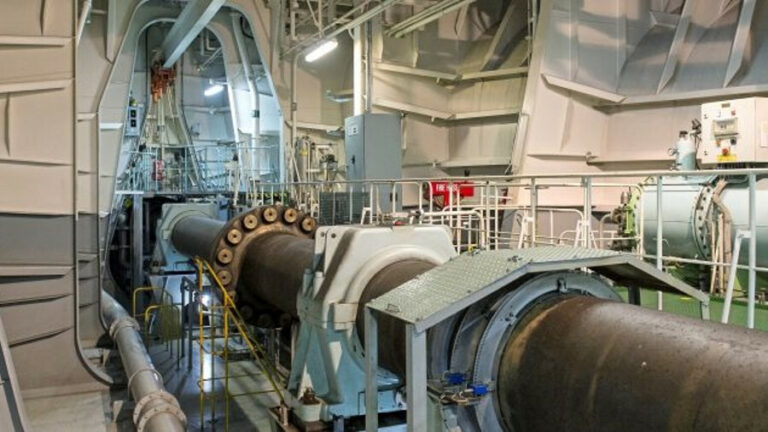

Alignment of the shaft line and main engine

Alignment of the shaft line and main engine – this is a critical technical operation that includes:

- Preparatory Work:

- Defect detection of all shaft line elements

- Checking the engine foundation condition

- Checking engine mounting

- Measuring existing clearances and positions

- Main Alignment Works:

- Main engine alignment relative to foundation

- Engine height and horizontal positioning

- Shaft line alignment relative to engine

- Checking the alignment of all shaft line elements:

- Engine crankshaft

- Intermediate shaft

- Propeller shaft

- Stern tube device

- Measurement Methods:

- Laser alignment

- Optical alignment

- Dial indicator measurements

- Hydraulic measurements

- Adjustment Works:

- Selection and installation of engine chocks

- Bearing position adjustment

- Coupling adjustment

- Clearance adjustment

- Control Operations:

- Cold condition alignment check

- Hot condition alignment check

- Vibration measurements

- Checking shaft journal bearing contact

- Documentation:

- Preparation of measurement protocols

- Preparation of alignment reports

- Coordination with classification society

Proper alignment is critically important for:

- Vibration reduction

- Bearing wear reduction

- Prevention of shaft line breakdowns

- Equipment service life extension

- Optimal main engine operation

Have a project in mind?

Lets us help you to suit your needs